For this reason, chemical composition and elemental impurity analysis are an integral part of the battery manufacturing process. molecular spectroscopy, as FTIR, Raman and NIRĮlemental composition and impurity analysis of battery materialĭeviations in chemical composition or impurities in electrode materials can significantly affect final battery performance.mass spectrometry, as ICP-OES & ICP-MS, GC-MS, IC-MS.In this section I would like to briefly highlight the benefits of various analytical techniques, including: Benefits of each analytical techniqueĮvaluation of batteries and battery components requires a variety of analytical methods that study materials and component surfaces at various scales. Overview of the solutions for physical, chemical and structural analysis of cathode, anode, electrolyte and separator material and structure. The infographic below provides a great overview of the solutions for physical, chemical and structural analysis of cathode, anode, electrolyte and separator material and structure.

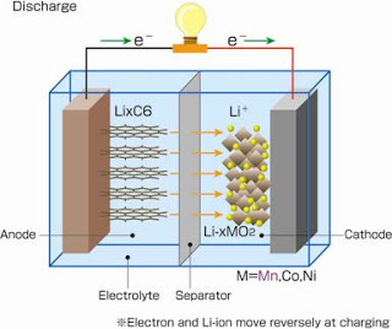

Likewise, development of new battery materials must ascertain all the critical parameters that could affect battery performance throughout the entire manufacturing process. Quality needs to be monitored at every stage from raw materials through to cell assembly to maintain production efficiency and minimize waste. Battery manufacturers must not only deliver consistent overall quality, but they must also deliver it throughout the manufacturing process. Increases in battery performance requires the development of new battery components as well as understanding and addressing the mechanisms that result in performance degradation with repeated charging and discharging cycles. The electrolyte is a chemical medium that allows the flow of electrical charge between the cathode and anode. There are three main components of a battery: two terminals made of different chemicals (typically metals), the anode and the cathode and the electrolyte, which separates these terminals. Analytical requirements in quality control and monitoring Table: Top 10 countries by estimated lithium-ion battery manufacturing capacities in 2025 (Source: S&P Global Market Intelligence). However, it’s clear that both battery demand and manufacturing capacity are set to grow. It’s important to point out that the battery industry is evolving rapidly, and current estimates could change due to economic or political circumstances. For instance, Germany’s capacity is projected to rise to 164 GWh, representing a 15-fold increase in just four years. While China is expected to come out on top, with estimated capacity around 65% worldwide, European countries are massively ramping up battery production. Heading toward zero emission goals the global lithium-ion manufacturing capacity is expected to more than double by 2025. European countries collectively make up for 68 GWh, or around 10% of global battery manufacturing. China is by far the leader in the battery race in 2022 with about 80% (about 558 GWh capacity) of global lithium-ion battery manufacturing capacity, followed by United States with only 6%, or 44 GWh (Source: S&P Global Market Intelligence). For that reason, developing domestic battery supply chains, including battery manufacturing capacity, is becoming increasingly important as countries strive to shift away from gasoline vehicles to electric mobility. With the rise of electromobility and the consequent increase in EV manufacturing, the market for lithium-ion batteries has seen consistently high growth rates. Lithium-ion battery manufacturing capacity It’s expected to reach 9,300 gigawatt hours (GWh) by 2030, which translates to a scale-up of about 20 times from 2020 levels. Global installed battery storage capacity is forecast to expand by 30-40% annually in the next five years - a trend that is likely to continue. Consequently, demand for lithium-ion batteries for electric vehicles (EV) is rising rapidly. The electric-vehicle revolution, driven by the necessity to decarbonize personal transportation to meet global targets for reductions in greenhouse gas emissions, is set to change the automotive industry radically.

0 kommentar(er)

0 kommentar(er)